2023

Tianyu Yu, Yige Fan, Zhixiang Zhang, Qingyu Hu, Weiye Xu, Haipeng Mi, Stefanie Mueller

Thermal interfaces in HCI have been widely explored. Previous work either used electronics that continuously consume energy to actively control the temperatures, or relied on materials that passively create only one predefined temperature behavior, which both leave the gap of exploring objects that allow self-contained programmable temperature behaviors, utilizing materials’ dynamic thermal properties.

To address this gap, we introduce Thermaterial, a method using fluidic composites with controllable thermal properties to enable temperature behaviors without continuously consuming energy, instead utilizing programmed ambient heat transfer behaviors.

Contributions:

- Led the project, including conceptualization, experiments, design and fabrication methods, and application demonstration.

Thermaterial

Tunable thermal-conductive composites

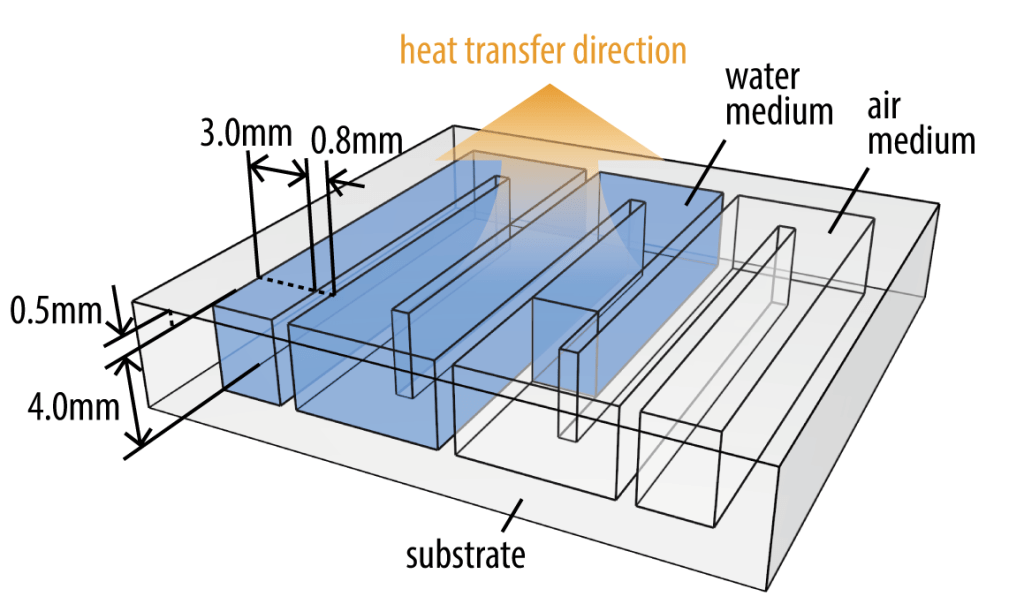

We designed a fluidic composite with fluidic channels embedded. By altering the material compositions through the infilled fluidic medium (e.g., water with a thermal conductivity of 0.6W/(m·K) and air with a thermal conductivity of 0.026W/(m·K)), we can adjust the overall thermal insulance and heat capacity of the composites accordingly.

Theoretically, a lower water-flling ratio will cause a larger thermal insulance of the composites, since air is much less thermally conductive than water. In a quantitative experiment, we adjusted the water-filling ratio from 0% to 100%, and the results showed changes in the thermal insulance of up to 3.0 times, which is comparable with related methods in material science.

Thermaterial composites with tunable thermal insulance

Quantitative experiment to evaluate the tunable insulance of Thermaterial

Fabrication of the composites

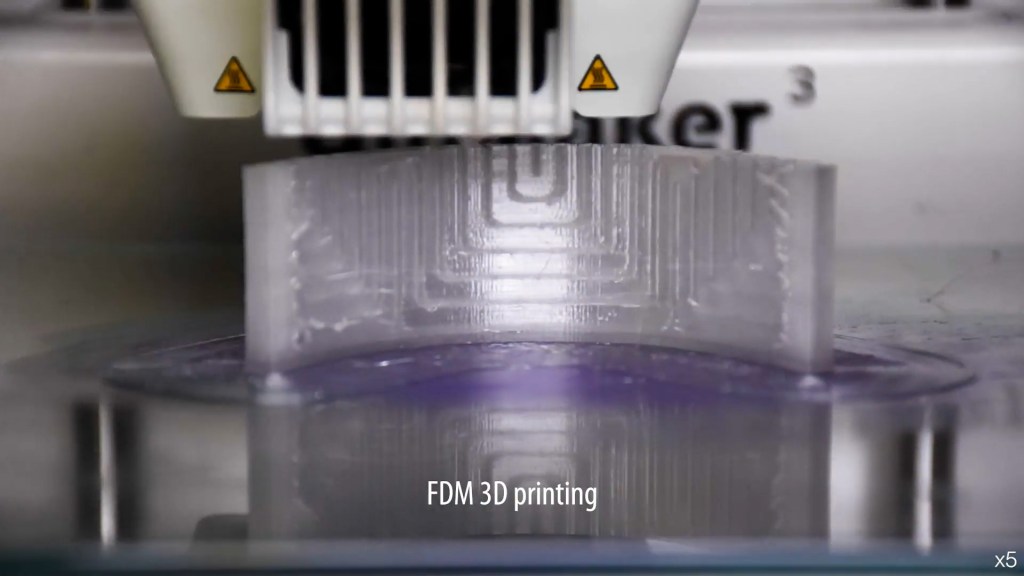

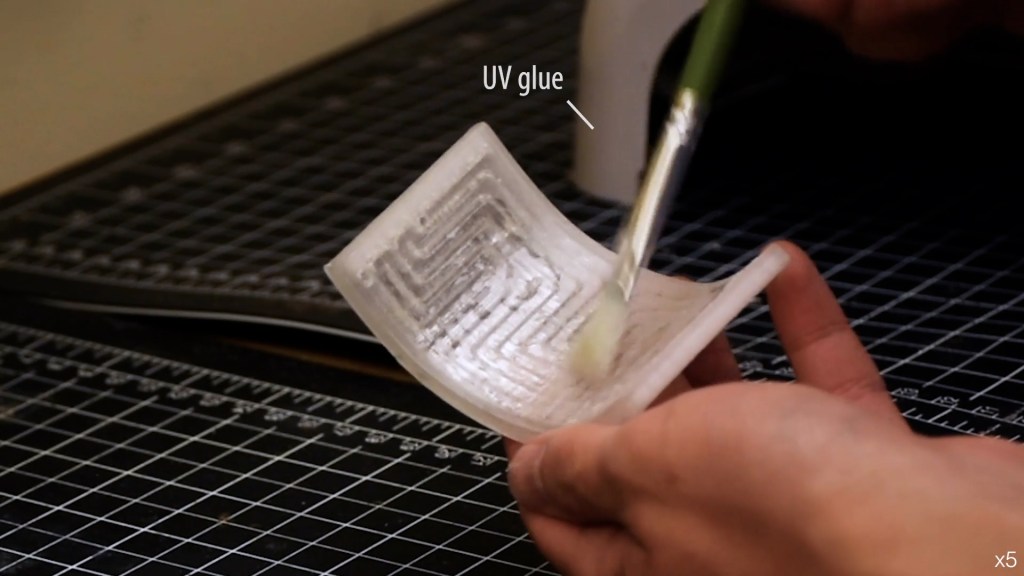

We demonstrate a series of methods to fabricate both the rigid and the flexible versions of the composites, as well as the method to configure the thermal insulance of the composites.

Fabricate rigid composites with 3D printing and post-processing steps.

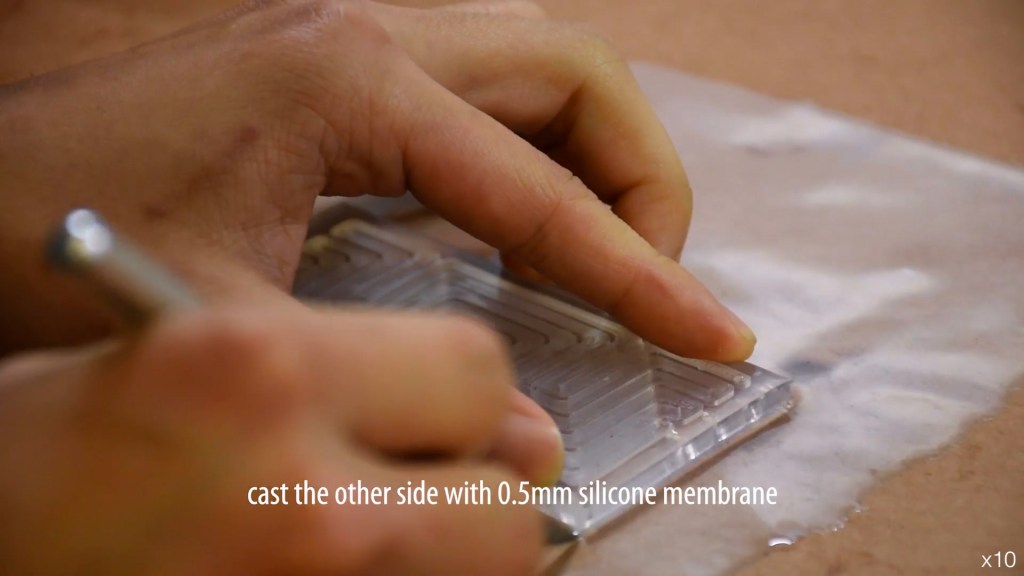

Fabricate flexible composites with silicone casting.

Install the internal fluidic medium to configure the thermal insulance.

Applications

Reconfigurable passive thermal marker

The figure illustrate two thermal markers infilled with different fluidic patterns of water and air medium.

When attached to a heated surface, e.g., a heating machine enclosure, due to the difference in the thermal insulance of water and air pixels, their surface temperatures will stay different as a result of stable heat transfer. Users can observe distinct thermal patterns through a thermal camera.

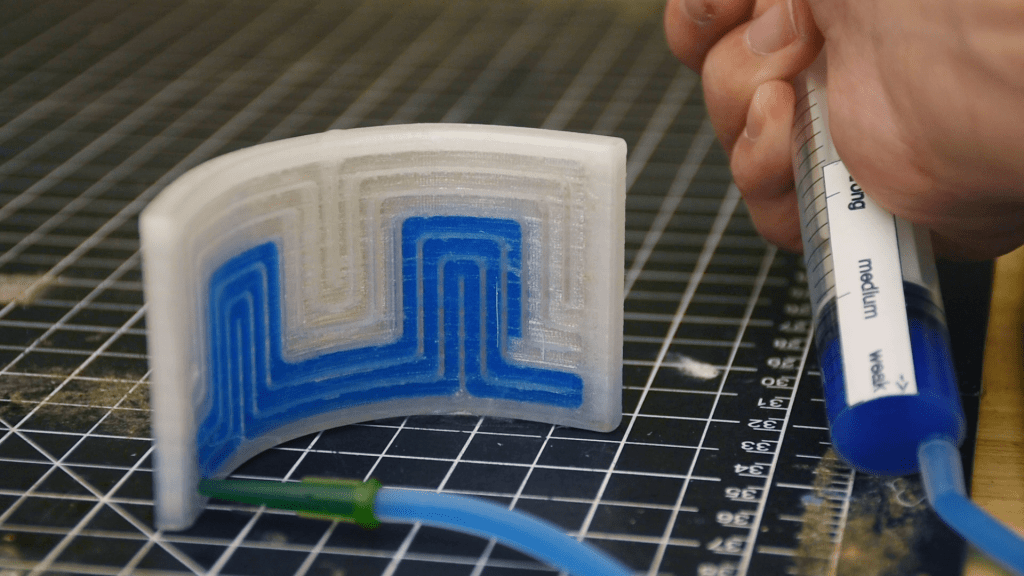

Tunable thermal wearable

The figure demonstrates an exemplar ice therapy wearable, where the inner skin-contacting layer is fabricated with a piece of flexible Thermaterial.

Users can adjust the cooling skin-contacting temperature by altering the water-filling ratio of the Thermaterial. These results suggest potential application scenarios such as customized injury therapy or rehabilitation.

Customized thermal-insulated layout in a container

The figure showcases a lunch box, which contains one left cooling tank, one right heating tank, and two intermediate tanks, where the walls between the inter mediate tanks and adjacent cooling and heating tanks are made with Thermaterial.

This design allows users to adjust the heating and cooling effects applied to the intermediate tanks through the Thermaterial walls by altering the water-filling pattern. Such a method may provide a low-tech approach for preserving temperature-sensitive items, e.g., food or medicine, within different temperature environments inside the same container.

Dynamic thermal-insulated enclosure

The figure shows a proof-of-concept prototype of a battery box using Thermaterial as the enclosure. The box contains a silicone heat pad inside, imitating the battery that generates heat.

By adjusting the water-filling ratio of the enclosure, the heat dissipation rate of the battery box can be modified. This enclosure can be used to mitigate the internal temperature fluctuation in devices experiencing varying inner heating power or fluctuating ambient temperatures.

Further detials: Thermaterial: Program Ambient Heat Transfer Behaviors on Objects through Fluidic Composites (CHI EA ’24)